Components, Accessories and Related Equipment

LoadLifter Vacuum Bag-Lift System

Pick. Slide. Release. Repeat!

LoadLifter Vacuum Bag-Lift Assist Device - Pick, Slide, Release...Repeat!

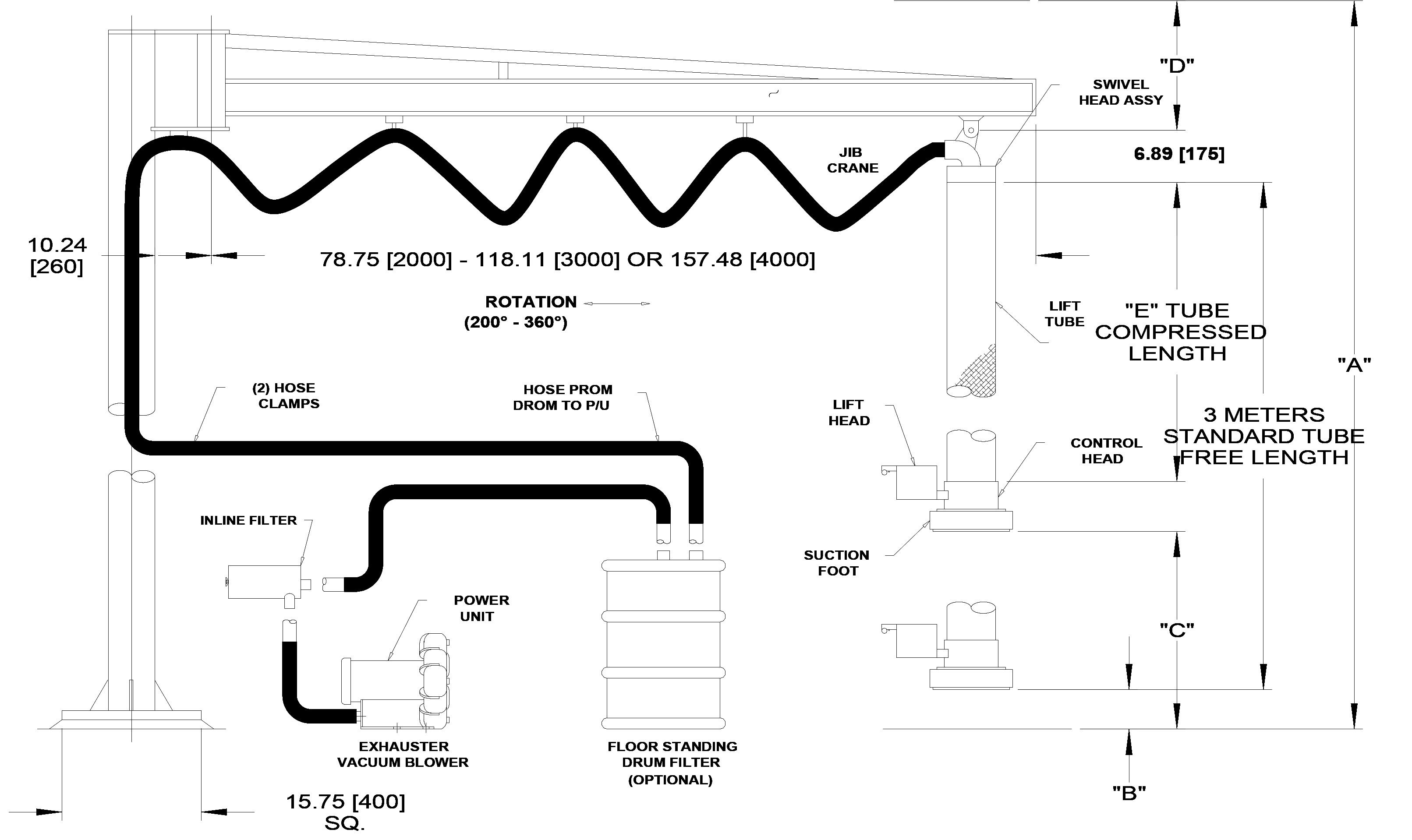

Remote-mounted vacuum producer outside of explosion-rated area. Optional stainless steel free-standing pedestal and boom are engineered to complement a VAC-U-MAX bag dump station.

• Designed to reduce risk of injury from repetitive motion tasks, specifically paper bag or small sack emptying activities in the dry bulk environment.

• Reduces fatigue from extended bag-emptying operations e.g. mixer loading.

• Pivoting boom, sliding trolley and swiveling lift tube reduce twist-and-carry strain when pallets of bags are not near the bag dumping station.

• Available with support column for free-standing installation, or with jib-boom mounting on a wall or steel column.

• Designed for vacuum lifting of non-porous paper or plastic bags.

• Safety filter with extra-large cartridge element captures fugitive dust coatings on the bags before entering the vacuum producer. The large surface area and dust holding capacity of the drum is also important if a bag breaks during the lifting operation.

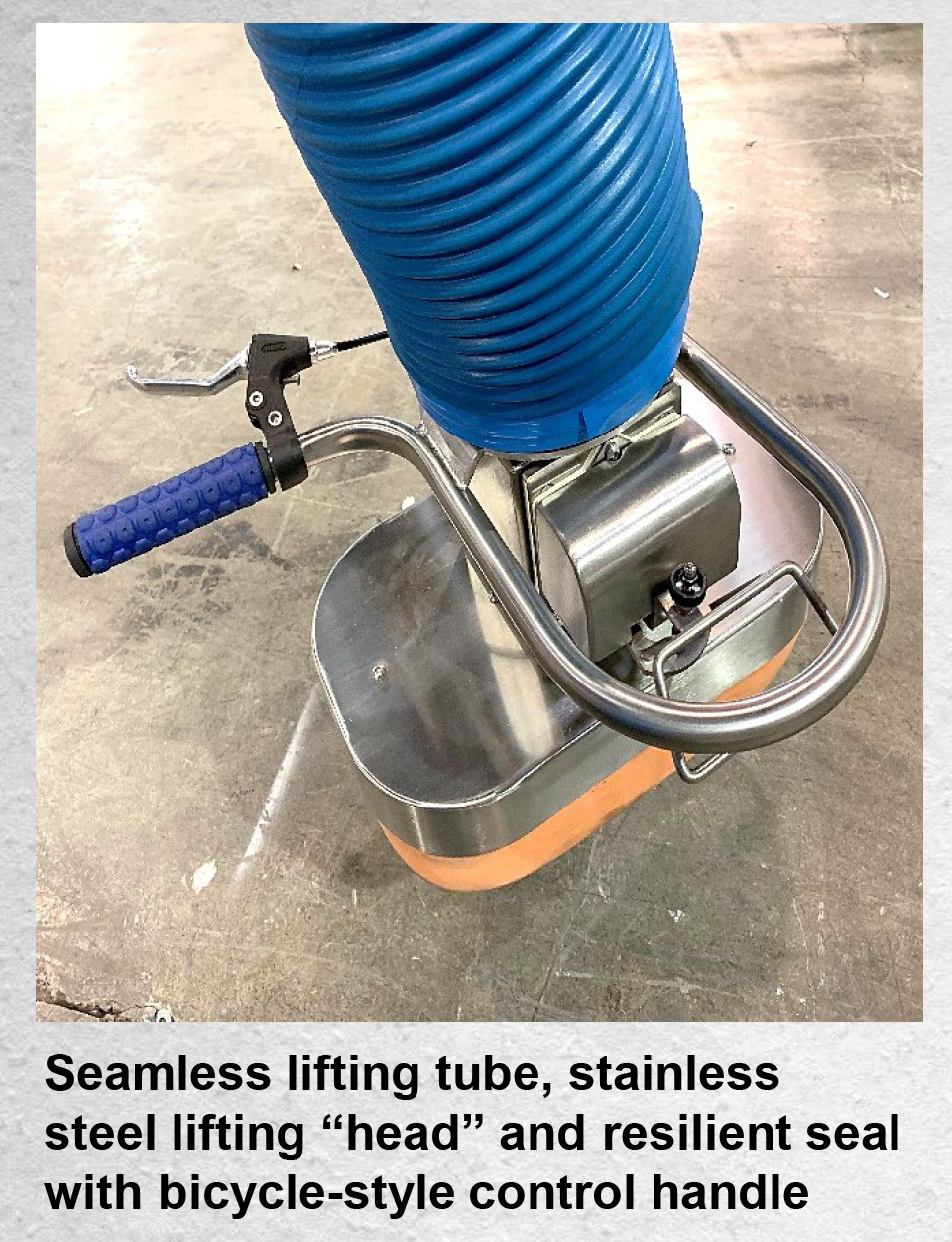

• Purpose-built bag lifting head with suction control (lift / release) reduces operator strain when handling the bag.

• Vacuum producer: continuous-duty direct-drive exhauster with 5HP (3.75kw) TEFC motor. Exhauster is equipped with high-temp bearings and grease and cast aluminum impeller and housing.

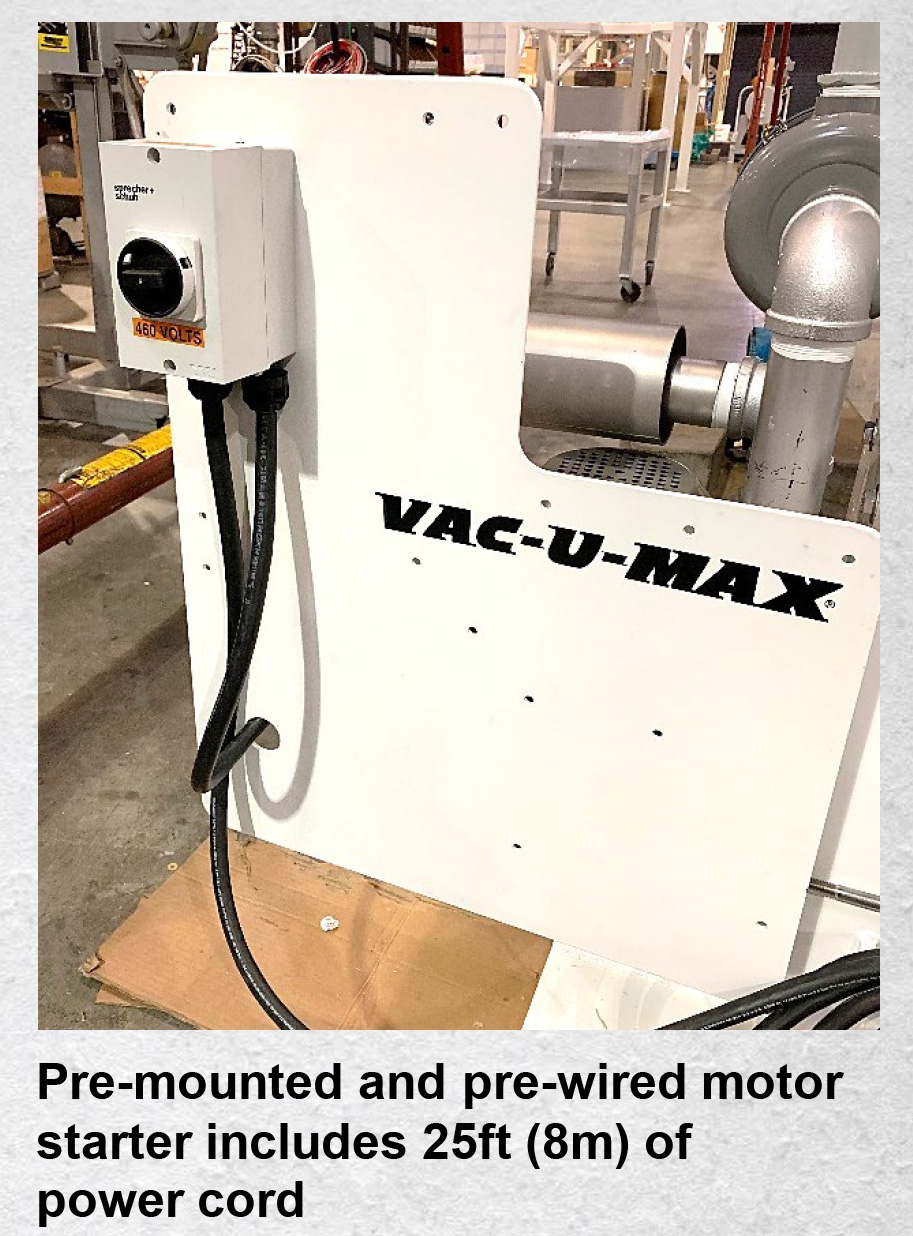

• Motor starter, NEMA 4, pre-mounted, includes 25ft (8m) of 4-wire power cord.

• Options: custom boom lengths, custom lifting tube heights, remote vacuum producer, SS construction of boom and pedestal.

Features

- Vacuum producer on mounting plate for freestanding version. Plate can be repositioned in 90° increments

- Extra-large safety filter and collection drum protects the vacuum producer and plant environment if a bag breaks

- Seamless lifting tube, stainless steel lifting “head” and resilient seal with bicycle-style control handle

- Pre-mounted and pre-wired motor starter includes 25ft (8m) of power cord

Website

Website