What is Vacuum Conveying?

What is Vacuum Conveying?

How does Vacuum Conveying Work?

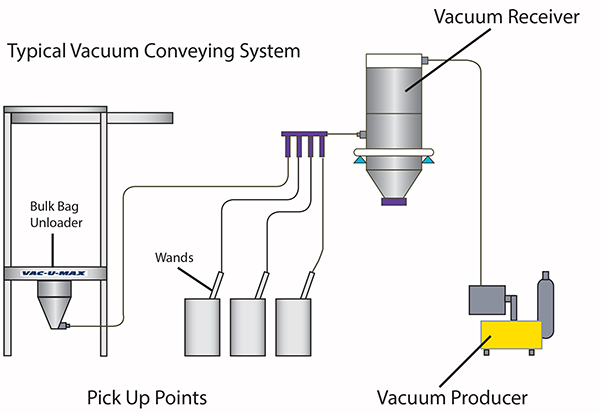

Vacuum Conveying is the process of moving bulk dry materials, such as powders, from place to place within a factory using suction. The material is transferred in a network of tubing from the pick up point or source to the customers process. Most Vacuum Conveying System transfer product based on a timed interval to the vacuum receiver. At the end of the timed sequence the discharge valve can open and the material conveyed can discharge in to the process.

There are two types of vacuum conveying. Dilute phase conveying and Dense phase conveying.

- Dilute Phase Conveying the material is entrained in the air stream and the is an almost equal part of air and product. This method is excellent for conveying almost any type of powder like sugar or flour.

- Dense Phase Vacuum Conveying the material is transferred in slugs within the convey tubing. The material moves slower then dliute phase conveying and is excellent choice for friable product or a blend of powders.

10 Considerations for Pneumatic Conveying System Design

Food processors are experts at producing food products, chemical manufacturers are experts at developing chemicals, pharmaceutical companies are experts at making drugs, and pneumatic conveying manufacturers are experts at moving bulk solids. Just as it is not necessary to become an expert on how to build a vehicle when purchasing one, it is also not necessary for users of pneumatic conveyors to become experts at vacuum conveying to incorporate them into their processing line. While it is a good idea to have a broad understanding of how pneumatic conveying systems work, no pneumatic conveyor manufacturer will ever ask a customer if they need a dense phase or a dilute phase system. There are, however, many other questions a conveyor manufacturer will ask about a process, and the materials used in that process, that will aid them in designing a system with the necessary components to provide a solution that integrates into a customer’s process.

- Material Bulk Density

- Conveying Distance

- Conveying Rate

- Batch vs. Continuous Conveying

- Material Characterisitcs

- Material Container Receipt

- Pick Up Point

- Process Equipment

- Headroom

- Plant Site and Industry Environment

Read the full article here: http://www.vac-u-max.com/case_histories.cfm?case=22

Advantages of a VAC-U-MAX Vacuum Conveying System

- Dust Free Transfer of Powder. As opposed to positive pressure conveying leakage in a vacuum system is inward. This means for a dust free envionment.

- Easy to Clean. VAC-U-MAX Vacuum Conveying System offer quick take apart without tools.

- Small Foot Print. Using a Vacuum conveyor the tubing or hose takes up little or no floor space within your facility

- Efficient conveying method of powders

- Easy to install. All VAC-U-MAX systems are pre-assembled and shipped for easy installation when it arrives at you factory. Most VAC-U-MAX Vacuum Receivers are equipped with a suspension frame that allows for support from above or below.

- Low Power Consumption.

Vacuum Conveying SystemsVAC-U-MAX Basic Vacuum Conveying Systems consist of a Single Pick-Up Point, a Single Vacuum Receiver and... |

|

.JPG)

Website

Website